What we specialize in

As the world's most powerful new material product manufacturing platform, our missions are to support national defense construction, serve significant national projects, boost national economy and improve people's living quality, and we are committed to high-end oriented development, mass production and globalization of new materials, and strive to develop "new materials for the country". In this field we have listed companies including Beijing New Building Materials Public Limited Company (stock code: 000786), China Jushi Co., Ltd. (stock code: 600176) and Sinoma Science & Technology Co., Ltd. (stock code: 002080). We now have a production capacity of 2.8 billion square meters of gypsum boards, 3.21 million tons of glass fibers and 15 GW of wind turbine blades, all ranking first in the world. Our products, such as carbon fiber, lithium battery separator, silicon nitride ceramics, waterproofing materials and coatings, are blooming, and their scale and influence are increasing.

Gypsum board. We are an industry-leading manufacturer of green gypsum boards. We have developed the world's first "Luban multifunctional board", phase change gypsum board, aldehyde-removal gypsum board and other green products to create a green whole house assembled building system featuring “personalized design, factory production, assembled construction, and ready to move in immediately after decoration”. Our products have been widely used in many key national projects, and in response to the call of the Belt and Road Initiative, we have deployed our products in many countries of Asia and Africa, and are gradually securing a global presence for our full product range.

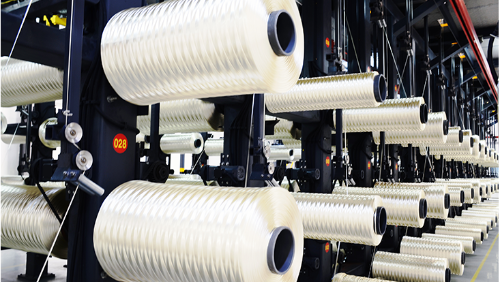

Glass fiber is a new-generation composite material to replace steel, wood, stone and other traditional materials, and is a national strategic emerging industry, which is of great significance to national economic development, transformation and upgrading. As the world's largest glass fiber manufacturer, we occupy a dominant position in the glass fiber market. Our self-developed glass fiber pool kiln drawing technology has won the second prize of the National Science and Technology Progress Award. We have built the first large-scale pool kiln wire drawing production line in China, the first 10,000-ton glass fiber production line in China and the first large-scale glass fiber production line overseas. Our products serve 5G communication, transportation, national defense engineering and other major national projects, with a global market share of over 30%.

In the field of wind power, we have a national-level enterprise technology center, Key Laboratory of Offshore Wind Turbine Blade Design and Manufacture Technology of Jiangsu Province, and a CNAS-accredited full-scale blade testing center. We have built many blade production bases in China, covering Jiangsu, Xinjiang, Liaoning, Yunnan, Henan, Hebei, Jiangxi, Gansu, Inner Mongolia, Jilin, etc. Our products range from 1.0 MW to 12.0 MW, with more than 100 models, and are sold to the United States, Thailand, Pakistan, South Korea and other countries. We have developed China’s longest 90-meter 6 MW blade with carbon fiber composite main beam and China’s largest 102-meter 11 MW all-glass fiber offshore blade, creating a number of national records.

In the field of carbon fiber, we have achieved a breakthrough from 0 to 1. Our self-developed independent and controllable high-end carbon fiber technology won the first prize of National Science and Technology Progress. Our products are widely used in aerospace, transportation, new energy, infrastructure and other fields. We have participated in the formulation of the first international carbon fiber standard based on Chinese technology, and have realized the industrialized mass production of 10,000-ton T700, 1,000-ton T800 and 100-ton T1000 carbon fibers. In 2021, we built China’s largest high performance carbon fiber base in Xining, marking a new era of industrialization of domestic carbon fiber.

We have international advanced wet process separator manufacturing equipment and leading technology research and development capabilities, and have realized the localization of the last key material in lithium battery materials. We have 5-20 μm wet process separators and various types of coated separator products for new energy vehicle power batteries, 3C consumer batteries, energy storage batteries and other fields to help the country achieve the carbon peaking and carbon neutrality goals at an early date.

We produce advanced ceramics including high-performance ceramic wave-transmitting materials, ceramic insulation materials, special ceramic fibers, special functional coatings, high-temperature ceramic membranes and equipment, with high added value, high technological content, and low energy intensity, providing key products for national defense, military, aviation, aerospace, energy conservation, environmental protection, high-end equipment manufacturing, electronics, information and other industries.